TCO Savings Analysis

Battery Intelligence Impact on Fleet

Electrification TCO Savings Analysis

In the evolving landscape of commercial fleet operations, the shift toward electric vehicles (EVs) presents a compelling case for cost optimization through battery data management, with potential benefits ranging from $50,000 to $150,000 per vehicle over its lifetime. Battery intelligence plays a crucial role in achieving these savings through several interconnected mechanisms that work together to optimize fleet operations and reduce total cost of ownership (TCO).

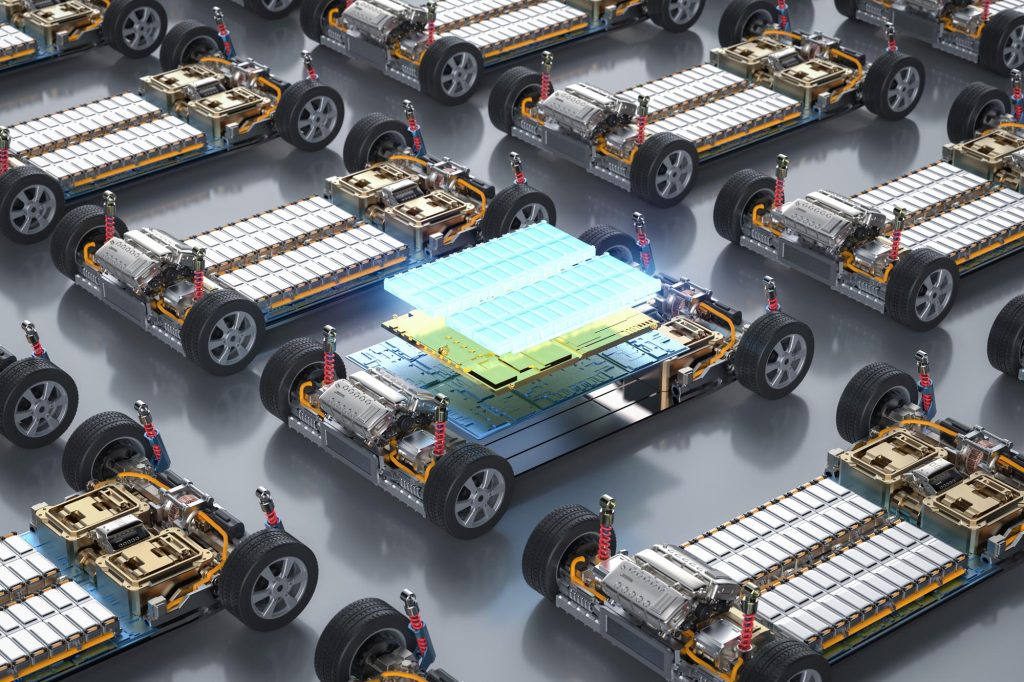

Battery Lifecycle Enhancement

At the heart of the cost-saving equation lies battery lifecycle optimization,

which can contribute between $15,000 and $40,000 in savings per vehicle.

Smart charging management stands as the cornerstone of these savings,

as it employs sophisticated algorithms to determine optimal charging patterns that significantly reduce battery degradation.

By implementing these intelligent charging strategies, fleets can extend their battery life from the typical 5-7 years to an impressive 8-10 years or more.

This extension translates directly to delayed replacement costs, which typically run $20,000- $30,000 per vehicle.

Battery intelligence systems directly impact battery longevity

and performance through

1. Smart Charging Management

- Optimal charging patterns reduce degradation by 15-20%

- Extended battery life from 5-7 years to 8-10 years o Reduced replacement costs averaging $20,000-$30,000 per vehicle

- Temperature-optimized charging reducing stress on battery cells

2. Performance Optimization o Real-time voltage and current monitoring

- Cell balancing for optimal performance

- Depth of discharge management

- Thermal management optimization

The intelligence system continuously monitors voltage and current levels while managing cell balancing and depth of discharge. These features work in concert with thermal management systems to ensure optimal battery performance under varying conditions.

The result is a battery that not only lasts longer but also maintains its performance characteristics throughout its extended life.

Energy Management and Cost Reduction

Energy consumption optimization represents another substantial area of savings, potentially reaching $10,000 to $35,000 per vehicle. Through sophisticated charging strategies, fleets can take advantage of off-peak electricity rates, leading to annual savings of $3,000 to $8,000 per vehicle. Smart grid integration further enhances these benefits by enabling participation in demand response programs, which can generate additional annual revenue of $1,500 to $4,000 per vehicle.

Intelligent battery management enables

1. Charging Strategy Optimization

Off-peak charging savings: $3,000-$8,000 annually

Smart grid integration benefits: $2,000-$5,000 annually

- Demand response program participation : $1,500-$4,000 annually

2. Route and Usage Optimization

Energy-efficient routing based on battery status

Regenerative braking optimization

Climate control pre-conditioning

Load and terrain-based energy management

The intelligence system’s ability to optimize routes based on real-time battery status and environmental conditions leads to significant energy efficiency improvements. By considering factors such as terrain, load, and weather conditions, the system can recommend the most energy-efficient routes and driving patterns. This holistic approach to energy management ensures that every kilometer driven is as cost-effective as possible.

Maintenance and Downtime Reduction

Predictive maintenance capabilities enabled by battery intelligence systems contribute substantially to cost reduction, offering savings between $12,000 and $40,000 per vehicle. By detecting potential issues before they become critical failures, these systems help avoid expensive repairs and minimize downtime. Early problem detection can save $5,000 to $15,000 per major issue avoided, while reduced downtime translates to savings of $2,000 to $5,000 annually per vehicle.

Predictive maintenance enabled by battery intelligence

1. Early Problem Detection

- Battery fault prediction saving $5,000-$15,000 per major issue

- Reduced downtime costs: $2,000-$5,000 annually

Prevention of catastrophic failures: $10,000-$20,000 per incident

2. Maintenance Schedule Optimization

Condition-based maintenance versus time-based

30-40% reduction in routine maintenance costs

Extended service intervals based on actual usage

The shift from traditional time-based maintenance to condition-based maintenance represents a paradigm change in fleet operations. By basing maintenance schedules on actual usage patterns and battery condition rather than fixed intervals, fleets can reduce routine maintenance costs by 30-40% while ensuring optimal vehicle performance and longevity.

Operational Efficiency and Asset Utilization

Battery intelligence transforms fleet operations by enabling data-driven decision-making, resulting in operational efficiency improvements worth $8,000 to $20,000 per vehicle. Real-time range prediction and dynamic dispatch capabilities ensure that vehicles are assigned to routes that match their current battery capacity and condition. This optimization reduces the need for reserve vehicles and improves overall fleet utilization.

Battery intelligence provides

1. Fleet Utilization Optimization

- Real-time range prediction

- Dynamic dispatch based on battery state

- Optimal vehicle-route matching

- Reduced reserve fleet requirements

2. Performance Analytics

- Driver behavior optimization

- Range anxiety reduction

- Improved asset utilization

- Enhanced route planning

Performance analytics provide insights into driver behavior and route efficiency, helping fleet managers make informed decisions about vehicle deployment and training needs. The system’s ability to reduce range anxiety through accurate predictions and proactive alerts contributes to smoother operations and higher driver confidence.

Residual Value Protection

The impact of battery intelligence extends to the vehicle’s end-of-life value, protecting an additional $5,000 to $15,000 in residual value per vehicle. By maintaining detailed records of battery health, charging history, and maintenance activities, these systems provide future buyers with confidence in the vehicle’s condition. This documentation, combined with optimized usage patterns and protected battery capacity, results in higher resale values compared to vehicles without intelligent battery management systems.

Battery intelligence contributes to higher resale values through

1. Battery Health Documentation

Verified battery state of health

Complete charging history

Performance degradation tracking

Warranty compliance verification

2. Life Extension Features

Documented maintenance history

Optimized usage patterns

Protected battery capacity

Understanding the Savings Range

The wide range in potential savings, from $50,000 to $150,000 per vehicle, reflects the varying operational contexts in which electric vehicles are deployed. Vehicles operating shorter daily routes in moderate climates typically realize savings at the lower end of the spectrum, while those in demanding conditions with longer routes tend to achieve higher savings.

Heavy-duty vehicles with larger battery capacities in extreme climate conditions often see the greatest benefits from battery intelligence systems, as the impact of optimization becomes more pronounced with increased vehicle size and operational demands.

Variable Factors Affecting Savings Range

Lower Range ($50,000) Typically Applies To

• Shorter daily routes (<100 miles)

• Moderate climate conditions

• Light-duty vehicles

• Regular urban operations

• Smaller battery capacity vehicles

Higher Range ($150,000) Typically Applies To

• Long-haul operations (>200 miles daily)

• Extreme climate conditions

• Heavy-duty vehicles

• Demanding duty cycles

• Larger battery capacity vehicles

The return on investment timeline typically shows initial benefits in the first year through operational savings, with peak energy optimization and maintenance cost reductions becoming apparent in years two and three. By years four and five, fleets experience the full range of benefits, including maximum battery life extension and optimal fleet utilization, while residual value benefits materialize upon vehicle retirement or sale.

ROI Timeline with Battery Intelligence

Initial investment in battery management systems

Training and implementation costs

Beginning of operational

savings

Peak energy optimization

savings

Maintenance cost reductions become apparent

Operational efficiency improvements

Maximum battery life extension benefits

Full realization of maintenance savings

Optimal fleet utilization achieved

Residual value benefits materialize

Conclusion

Battery intelligence systems transform the TCO equation for electric fleets by enabling sophisticated optimization across multiple cost centers. By orchestrating improvements across multiple aspects of fleet operations, these systems help organizations achieve substantial cost savings while improving operational efficiency and sustainability.

The variation in savings from $50,000 to $150,000 per vehicle directly correlates with vehicle usage patterns, operational demands, and the extent of battery intelligence implementation. Organizations that fully leverage battery intelligence capabilities typically achieve savings closer to the higher end of the range, particularly in demanding operations where battery optimization has the greatest impact.

Get in Touch

If you are interested in joining us on this exciting journey, please reach out to us at

contact@batterfly.co.kr.

Let’s work together to drive the future of EV battery intelligence and

create a lasting positive impact on the environment and the industry.

Batterfly is a leader in Battery Intelligence

AI-Powered Battery Condition Evaluation

Batterfly leverages advanced AI models to continuously

monitor and evaluate the condition of EV batteries in real-time. By analyzing data from various sensors,

the company’s AI algorithms can accurately predict battery health, identify potential issues, and recommend proactive maintenance measures. This expertise ensures that EV batteries operate at peak

efficiency, extending their lifespan and reducing the risk of unexpected failures.

Residual Value Prediction

Batterfly’s machine learning algorithms assess the residual value of EV batteries based on 17 key influencing factors. This expertise helps stakeholders, including manufacturers and consumers, make informed decisions about battery replacement, resale, and repurposing. By providing accurate residual value predictions, Batterfly contributes to a more sustainable and costeffective battery lifecycle management.

Carbon Emission Reduction Quantification

Through its data analytics platform, Batterfly quantifies the carbon emission reductions achieved by optimizing battery usage and reusability. This expertise enables companies to track and report their environmental impact, supporting their sustainability goals and compliance with regulatory requirements. By promoting efficient battery management, Batterfly plays a crucial role in the global effort to reduce greenhouse gas emissions and combat climate change.